BATCHING PLANTS TECHNOLOGIES

All devices manufactured by OPEN Technologie implement the latest technologies available on the European market. We provide premium quality products at competitive rates. OPEN Technologie ensures and guarantees to all our customers the timeliness of its deliveries and reliability of its services, as well as the mobility and promptness of responses to emergency situations. Our company also offers accessories for silos, silos, screw (worm) conveyors, as well a wide range of spare parts for a concrete plant.

HEATING SYSTEMS FOR BATCHING PLANTS

This solution enables heating of aggregates and water used for production of a concrete mix for any existing technological lines. The system is used for heating any materials that are components of a concrete mix for temperature of a fresh concrete up to +15°C at outside ambient temperature up to -10°C.

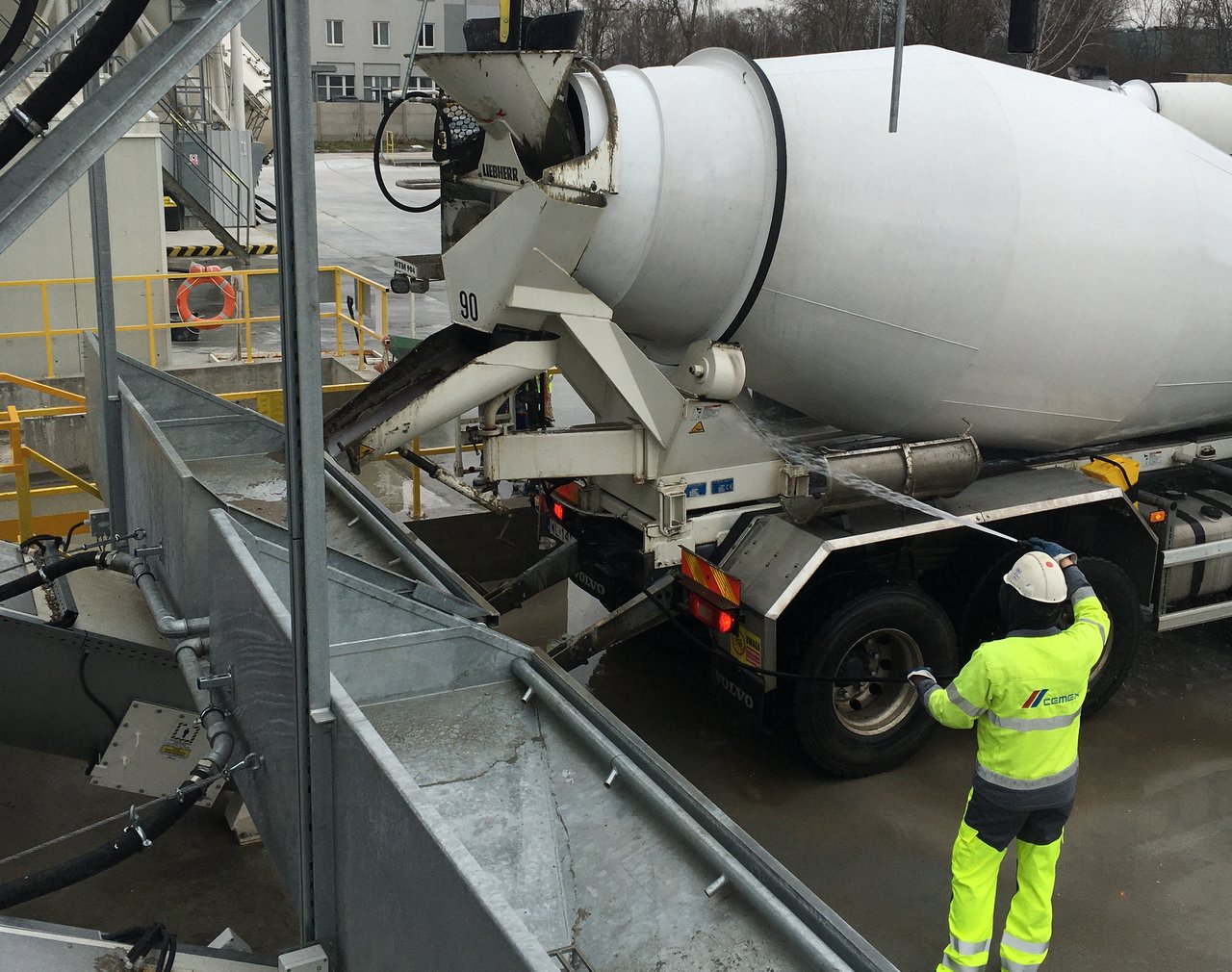

RECYKLING OF UNUSED CONCRETE

The concrete recycling system is used for flushing and separating any residual concrete from a mixer of concrete plants, concrete-mixers and truck-mixers, allowing the manufacturers of concrete mixtures to comply with the ecological standards, in particular with any standards related to protection of the natural environment.

TECHNOLOGICAL LINES

Our company ensures and provides design, production and installation of any new technological lines according to individual customer needs.

Specyfikacja

Drawings

HOUSING FOR TECHNOLOGICAL LINE

The design, construction and assembly of a housing in order to protect any devices against adverse weather conditions, enabling to carry out works in periods of the low outdoor temperatures as well providing protection against excessive dust and noise.

PRODUCTION MACHINES SERVICE

We also provide the comprehensive assembly and repair services for machines and complete technological lines. Our service teams include people with many years of experience in provision of such services and works which significantly reduces the time of response and time of failure removal. Correctness and thoroughness of all provided services is always approved and certified by our warranty.

Our company provides the comprehensive modernization of production lines on the grounds of our own projects or projects supplied by the Ordering Party. This work is aimed at providing and improving of the production efficiency, electrical energy savings, environmental protection and, most importantly, safety at work.